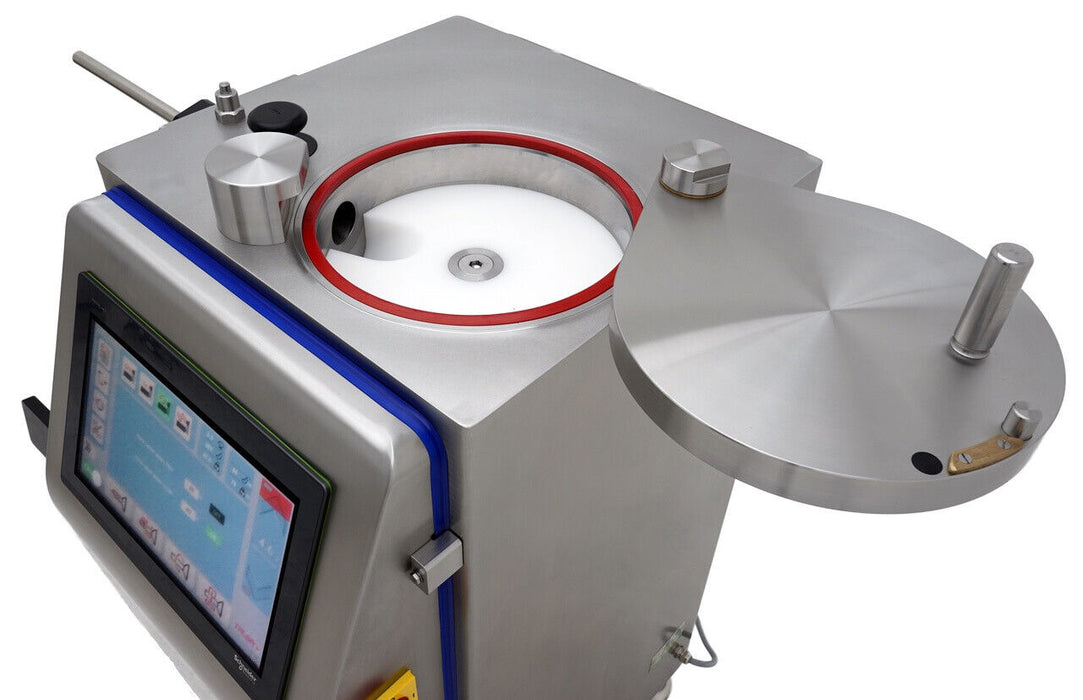

Talsa FPT30 30L Piston Stuffer With Digital Portioning & Twisting Horn

SKU FPT30

Original price

$0.00

Original price

-

Original price

Original price

Current price

$35,175.00

-

Current price

The Talsa FPT30 is expertly designed for medium-sized processors who need to fill and precisely portion a wide variety of food products with a single machine. With a 30-liter barrel capacity, it allows the production of medium or small batches without waste and offers quick product changeover.

Product Features

At Work

- Efficient Operation: Various assistance systems help the user find the most efficient way to achieve the desired product.

- Precision Calibration: Intuitive calibrating system produces exact weight portions in relation to product density.

- Adjustable Twisting: Horn adjustable twisting with manual casing hold.

- Visual Indicators: Clear visual indication of remaining product.

- Batch Tracking: Counters for batch/total number and weight.

Filling Mechanics

- Versatile Operation: 3 working modes—straight fill, portion, and twist.

- Programmable Functionality: Single or continuous operation with programmable portion numbers for automatic stop.

- Precise Portions: Portions range from 5 g up to 25 kg, with high precision of ±1 g.

- High Speed: Can produce up to hundreds of portions per minute.

- Adjustable Twisting: Number of horn twists adjustable from 1-15 revs.

- Programmable Fill Break: Customizable fill breaks for precise operation.

Frame

- Robust Construction: Entirely stainless-steel construction (AISI304), including frame, hardware, and components.

- Hygienic Design: Polished surfaces with CE radius for easy cleaning and compliance with hygiene standards.

- Waterproof Panels: Double-sealed access panels for water resistance.

- Stable Foundation: Adjustable, nonslip, vibration-absorbing stainless-steel feet.

Hydraulics, Electrics, and Electronics

- Powerful Performance: High-pressure hydraulic system driven by a 3 HP motor, suitable for the densest or coldest products.

- Temperature Control: Oil-cooling system with temperature control.

- Premium Components: Features top-brand components from Hydac Germany and Schneider Electric.

- Advanced Communication: Reliable and precise digital communication using Balluf Germany’s advanced I/O Link components.

Software and External Connections

- User-Friendly Interface: Control panel with a large 15” Schneider Electric digital touch screen displaying all information simultaneously in large size.

- Comprehensive Software: Intuitive software with numerous options, including interactive recipes that can be stored and executed directly on the machine’s screen.

- Industry 4.0 Ready: Digital solutions for maintenance, process integration, and custom solutions.

- Remote Support: Remote service and support access over a secure internet connection (ethernet cable or mobile phone).

Standard Equipment

- Included Horns: 5 horns with external diameters of 14, 20, 30, 38, and 43 mm.

- Hydraulic Oil: Supplied with the machine.

- Piston Extraction Wrench: Stainless steel wrench for piston extraction.

Specifications

- Barrel Volume: 7.9 gal

- Barrel Capacity: 55 lbs.

- Motor Power: 3 HP

- Portion Size: .08 oz - 55 lbs.

- Dosing Capacity: Up to 180 portions per minute

- Horn Twisting Speed: 1-15 twists per minute